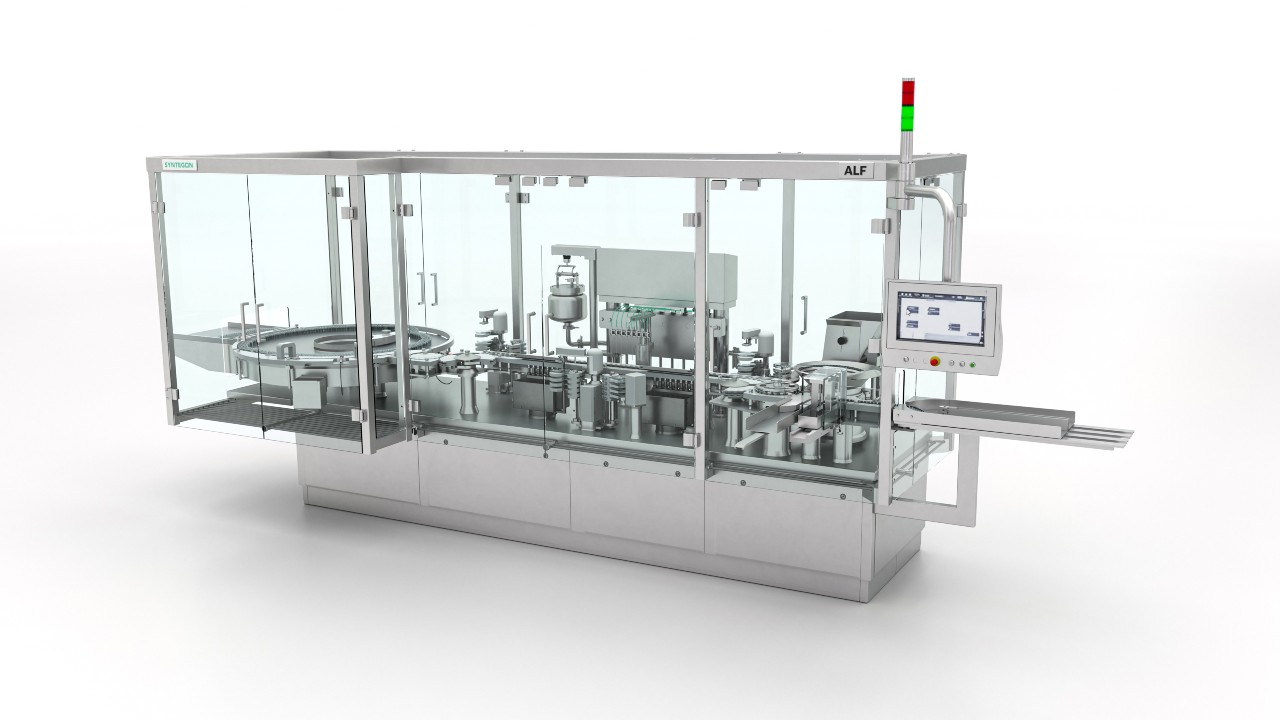

Syntegon Unveils Innovative Settle Plate Changer at Achema 2024 for Enhanced Aseptic Processing

Syntegon's new Settle Plate Changer at Achema 2024 revolutionizes aseptic processing with enhanced automation and compliance.

Breaking News

Jun 12, 2024

Ravindra Warang

At this year’s Achema 2024, held in Waiblingen, Germany, Syntegon Technology introduced its groundbreaking Settle Plate Changer (SPC), a patented development designed to automate viable monitoring in the aseptic filling process. This innovation is set to revolutionize pharmaceutical manufacturing by supporting compliance with the demanding EU GMP Annex 1 regulations.

The Settle Plate Changer enhances operational efficiency by automating the replacement of settle plates, which must be exchanged every four hours to ensure accurate environmental monitoring. Traditionally, this requirement has led to frequent production halts, but with Syntegon's new robotic handling unit, these interruptions are drastically reduced. Machines now only need to be stopped once daily for monitoring, significantly increasing yearly machine availability by up to 300 hours and promoting more sustainable manufacturing practices.

Steffen Gröber, Global Product Manager Service at Syntegon, highlighted the critical role of environmental monitoring in maintaining the sterility of aseptic processes. The automation provided by the SPC not only bolsters process reliability and traceability—with optional features like barcode scanning—but also aligns with Annex 1’s emphasis on minimizing manual operator intervention. This reduction in human involvement in the process zone decreases contamination risks by 80 percent, thereby enhancing product safety.

Muhammed Ali Turac, Project Manager Automation at Syntegon Service, emphasized that the development of the SPC predates the enactment of Annex 1, reflecting Syntegon’s proactive approach to compliance and customer-centric innovation. The device is available for new equipment purchases or as a retrofit for existing machinery, and it integrates seamlessly with both Syntegon and third-party machines and control systems.

This launch not only positions Syntegon at the forefront of pharmaceutical manufacturing technology but also ensures that existing equipment can continue to operate efficiently and sustainably, reducing downtimes and extending service life.